Polypropylene 2-side coated synthetic paper

PolyPA is a double side coated synthetic paper developed by ADEX in 4 thicknesses, 200, 275, 330 and 435 my.

The base is polypropylene (PP) to which is added a double side coating producing an adaptable, long lasting and resistant plastic. PP is considered to be a non-toxic waste product at its’ life end and with the correct equipment, in line with local regulations, it can be recycled.

PolyPA is compliant to EU 10/2011, USFDA, REACH and RoHS.

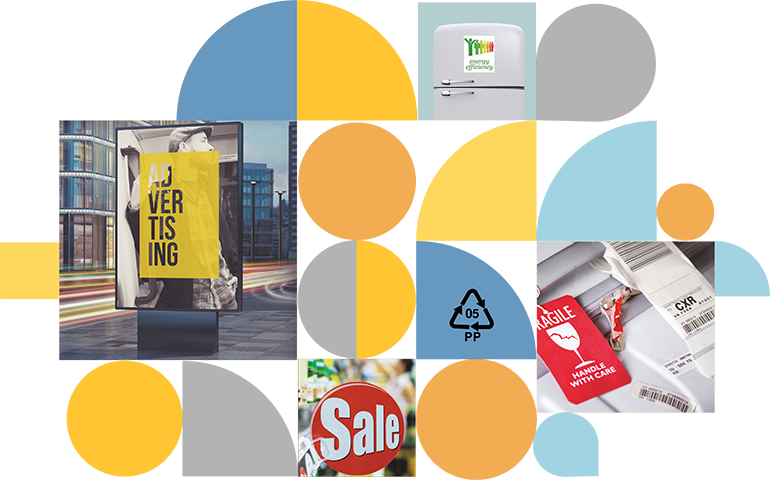

Applications:

- POP : Menu cards, posters, door hangers, banners and indoor billboards

- Commercial : Maps, golf cards, calendars, brochures, and flip charts

- Tagging : garment tags, baggage tags, glass bottle necks, food and agricultural labels

- ID and credentials : visiting cards, ID cards, mark-sheets and certificates

- Outdoor : front-lit and backlit displays for airports and train and bus stations as well as outdoor billboards

KEY Properties and Features

PolyPa has an incredible array of features.

POLYPA is:

- Easy to print, no grain direction

- Printable both sides

- Writeable with pencils and oil based pen inks

- Dimensionally highly stable

- Highly tear resistant

- Resistant to moisture

- Resistant to many oil and chemical substances

- Excellent single fold endurance

- Can be folded, creased, serrated, stapled, hot foil stamped, die punched and adhesive bonded

- Recyclable

- Anti-static

Due to the combination of the co-extrusion production process and to the highly innovative double sided coating, its stability and ink receptiveness makes for easy printing with Conventional Offset, UV Offset, Screen as well as UV Digital, Latex Digital printing and HP Indigo.

Formats

PolyPa is available in rolls and sheets.

The basic sheet size is 70 x 100 and for rolls the running length standard is 30 mt but can be adjusted according to customer needs.

For a full list of formats and prices ask for the latest price list from ADEX customer service, info@adexsrl.it

Recommendations for best results

Folding – both folding and scoring can be made with PolyPa. After folding it is recommended to keep the product under nipping for 30 minutes min.

Punching – given the nature of PP, best results are achieved with a round punch. A square punch if not correctly registered may cause tearing.

Die Cutting – blades should be sharp and free from nicks, avoid right angles and sharp corners as it may cause tearing. Right angle cuts should be made with 1/16 inch radius hole, use a double bevelled blade.